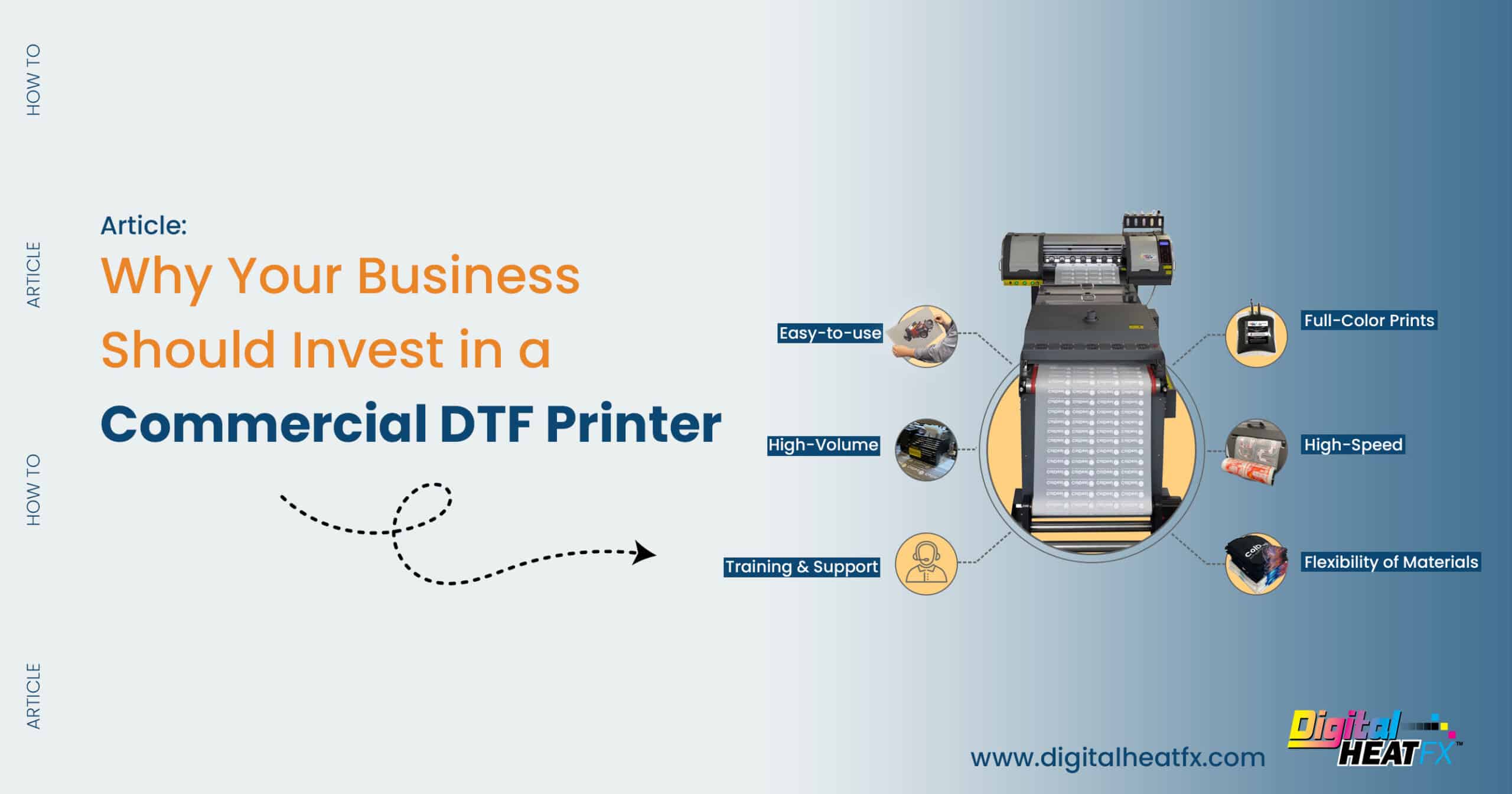

Why Your Business Should Invest

in a Commercial DTF Printer

For most decorators, the question is this: Should you switch (or upgrade) that old equipment you’ve been using for years? Or… can you go a few more years without upgrading?

Well, if you had this same question swimming in your head, hopefully, this little read gets you closer to an answer.

Throughout this page (and our time together), we’ll go over the basics, starting with what is commercial DTF printing, how it works, and what it is used for.

We’ll work our way up from there… and put our finger on the pulse of what people want, demand, and are willing to purchase.

Then after, we’ll look at some of the DTF advantages over traditional decoration methods.

And what better way to wrap it all up than with numbers (and ROI) at the end.

So, stick around because there’s plenty for us to cover!

What is Commercial DTF Printing?

Before anything else, let us first start with the basics and define what is direct-to-film (DTF) printing.

To give you a practical example that many of us are familiar with, consider white toner printing. In this method, a graphic is typically printed onto a special translucent PET (polyethylene terephthalate) film, which is then used to transfer your prints onto fabrics (or other substrates) using a heat-press mechanism.

It’s roughly the same process for DTF. The difference is to be found in the ink department. Direct-to-film systems run on liquid water-based inks instead of CMYK + W cartridges that are found in white toner printers.

However, apart from the differences in ink type used, there are other distinctions to consider. The more closely we look at it, the more key areas we can find where DTF sets itself apart from other traditional printing methods.

And one of those areas is speed. Compared to the DigitalHeat FX line of white toner printers, DTF systems print around 5-10x faster and can produce up to 300 ready-to-apply transfers an hour!

How they are able to pull that off is sort of question number one. So, let’s look at this next and see if we can make some sense of it all.

How Does DTF Printing Work?

We hope the above has put some things in perspective for you! To find an answer to how DTF printers are able to outperform just about anything else on the market today, we need to look into the inner workings of this printer and understand its functionality.

Typically, the process begins at the computer. To print anything, you first require a design. You can either purchase one online… or… create one yourself using graphics editing software such as Photoshop, Gimp, or Illustrator.

Once you have the design ready, you would send it over to the DTF printer.

With everything set up, all you need to do is load the DTF printer with consumables. There are three main consumables that feed into the printer: ink, adhesive powder, and PET film.

These consumables work together to produce your final print. With them replenished and fed into the printer, you can begin the printing process.

You can then press the print button to get going. Now, what’s going to happen is, the printer will take that translucent (and coated) PET film and roll it over to the print head for printing.

And this is where it gets a little technical.

Your design will get printed in a mirrored position, layer-by-layer. The color will be laid down first, followed by the white ink.

After the ink is applied, the DTF film passes through a powder-shaker unit. This unit deposits a type of polyurethane (TPU) hot-melt adhesive powder onto the back of the film (and ink), and to ensure even spreading, it is shaken by a vibrating mechanism.

Finally, the DTF film enters the heating chamber, which heats up the hot-melt glue and finishes curing the inks themselves, so that when it comes out the back it’s ready-to-go.

And there you have it, that’s how direct-to-film (DTF) printers work.

Next up, let’s look at things you can make with this printer, along with what people want, demand, and are willing to purchase.

If you’d like to read more about how DTF works, its benefits, pros, and cons, you can do so HERE.

What Can Direct-to-Film Print On?

Now that you know what DTF printing is and how it roughly works, the next natural question is, what will I be able to print on?

As expected, you can apply DTF transfers to a wide range of materials.

Keep in mind that it is unable to be used with hard surfaces, so explore both traditional and non traditional textiles.

- T-shirts

- Sweatshirts

- Sweatpants

- Hoodies

- Jackets

- Aprons

- Uniforms (e.g., for sports teams, workwear, or uniforms)

- Caps and hats

- Bags (e.g., tote bags, backpacks)

- Pillowcases

- Can Cooler Sleeves

- Denim

- And much, much more!

That’s a lot of items to get through! And that’s not even close to everything—there are way more items you can decorate that aren’t mentioned on this list.

You just have to put on your ‘’entrepreneurial hat’’ and think like them. What do people want from your shop? Is there anything specific they’re looking for? Is there a trend they particularly like right now? These are some of the questions you should ask yourself (and your customers).

Let’s keep moving forward and compare how DTF stacks up against traditional printing methods and weigh up the advantages.

Advantages of Commercial DTF Printing

If you’re using any of the classic printing methods, like a white toner printer or DTG, you probably need a pretty good excuse to switch things up and give DTF a shot.

Let’s take a high-level look at DTF and walk you through some of its main highlights. Maybe that will help you make up your mind on whether it’s the right tool for your projects.

1. Versatility with Materials:

- DTF printing can be applied to a wide range of materials including cotton, polyester, synthetic fabrics, silk, and more, catering to both light and dark fabrics without the need for expensive A & B paper.

2. Cost Efficiency:

- Savings of up to 50% on white ink costs.

- Consumables are notably more economical.

3. No Pretreatment Required:

- Eliminates the need for pretreating garments before printing, unlike Direct-to-Garment (DTG) printing methods.

4. No A+B Sheets Marrying Process:

- DTF printing skips the expensive and time consuming A+B sheets marrying process, common in white toner laser printers.

5. Production Speed:

- Streamlined production due to the elimination of pretreatment steps.

6. Washability:

- Proven durability comparable to or better than DTG, White toner transfers, and most other traditional printing methods.

7. Easy Application:

- Allows for effortless application of artwork on a wide range of garments and fabrics.

8. High Stretchability and Soft Hand Feel:

- In addition to effortless application, DTF transfers offer a soft to the touch, highly stretchable, and exceptionally durable product.

So, you can see there are a whole lot of benefits with direct-to-film (DTF) printing.

For some folks, it’s the production speed that matters the most. Others could be looking for something entirely different, like versatility with materials, long-term savings, or other advantages.

In the end, it all boils down to what sorts of projects you’re going to use it for. You, and only you, can determine this.

But enough about that already, because we have a lot more to talk about.

Setup Costs for Commercial Printing

Next up, let’s talk about how much it is going to cost to get your hands on a DTF printer and get the whole workflow up and running.

Now, we know this may not be the answer you were hoping for, but it will vary from person-to-person and company-to-company, depending on what equipment you may or may not already have, workspace, staff, location, and things like that.

What we can do, though, is tell you that the initial setup costs for DTF printing include investments in the DTF printer, heat press, software, and other essential equipment. While these costs can be substantial, they are balanced by producing high-quality prints and increased production efficiency.

Consumables such as PET films, printing inks, hot melt adhesive powder, and cover sheets are also necessary for DTF printing, contributing to the overall cost per print but ensuring desired quality and durability.

Labor considerations, including personnel for design creation, printing, heat transfer, and quality control, should also be factored into setup costs.

Automation systems can help reduce labor requirements, although initial training and setup are still required.

So, you can see there is no one easy answer to the question of how much it is going to cost to switch (or upgrade) to DTF printing.

Next, let’s work up a few imaginary numbers to estimate how much you might earn with this DTF printer.

Commercial DTF Printer Return On Investment

We get it. Investing a significant chunk of your budget into a DTF printer can feel a little uncertain, especially for those new to it.

You might find yourself torn between two likely outcomes and possibilities: fearing your money will get sucked away, or hoping it will pay off handsomely.

One way to look at it is there is no reason to worry IF you do your absolute best! And by that, we mean you do your homework—see how others run their businesses and what products they are actually taking to the shelf. What trends are you seeing in your part of the market that you haven’t tapped into?

Once you can spot these kinds of things, it’s on you to make them real!

That, combined with all the bells and whistles that direct-to-film (DTF) printers offer, helps you deliver high-quality prints with faster turnaround times and lower production costs compared to traditional methods.

To better illustrate this, let us provide you with a practical example. Above, we’ve created a video demonstrating a real-world client project, walking you through the entire DTF process, complete with details on consumable costs and profit margins.

Once you’ve gone through it, we can continue our conversation with you on DTF cost-effectiveness against screen printing.

Commercial DTF Printer Cost-Effectiveness Against Screen Printing

Screen printers out there are curious to know what the DTF printer’s cost-effectiveness is compared to screen printing.

In broad strokes, DTF printing is much more cost-effective for small to moderate (hundreds of transfers) print runs due to the absence of separate screens for each color, space needed to operate, cost of time to produce, and additional chemical supply costs.

However, for very large print runs with a small amount of colors, screen printing is truly a great option.

Investing in DTF Printing for businesses aiming to stand out in a competitive market, can be a strategic move.

Leveraging the advantages of DTF printing enables businesses to offer customers high-quality, customizable products with efficient production processes, ultimately driving growth and success in the commercial printing sector.

Questions? Want to know more about

DigitalHeat FX line of direct-to-film (DTF) printers?

Visit digitalheatfx.com and Live Chat with a Pro below,

or call 855-348-4839 to speak with a product specialist today.