PRINT HUGE – 13 X19 INCHES!

Introducing DigitalHeat FX 9541

DigitalHeat FX is proud to announce the latest addition to our growing fleet of white toner digital transfer printers, the OKI 9541wt LED System with its ability to print HUGE 13″ x 19″ transfers. The DigitalHeat FX 9541wt printer changes the game in transfer printers. Read on to learn why this printer can deliver a transfer better than any other printer on the market today.

PRINT HUGE – 13 X19 INCHES!

Introducing DigitalHeat FX 9541

DigitalHeat FX is proud to announce the latest addition to our growing fleet of white toner digital transfer printers, the OKI 9541wt LED System with its ability to print HUGE 13″ x 19″ transfers. The DigitalHeat FX 9541wt printer changes the game in transfer printers. Read on to learn why this printer can deliver a transfer better than any other printer on the market today.

It starts with the technology

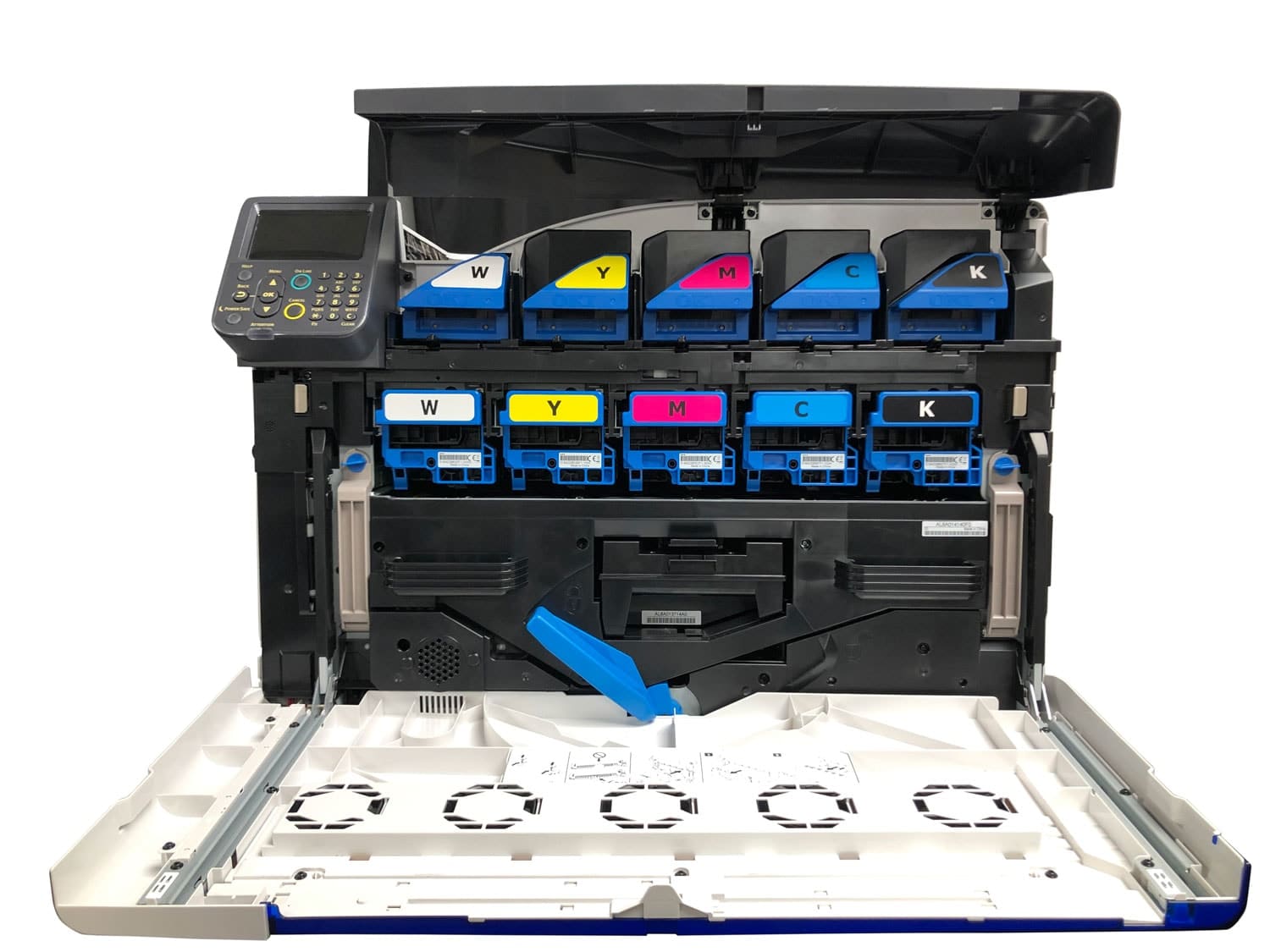

This is where we can get very deep into numbers and stats that aren’t interesting to read when first investigating a print system, so we will start with a summary. The DigitalHeat FX OKI 9541wt [Now branded the “Crio” 9541WTD white toner printer] is the first transfer printer to offer a 5 channel system delivering CMYK (just like most toner printers) plus a white channel. This means you get extremely rich colors, better than any other transfer printing solution in existence. This 5 channel system is powered by a 5 LED Electrophotographic printer that outputs an amazing 1200×1200 dpi. This combination of technology gives you the most powerful transfer printer on the market today!

CMYK+W

“Having ColDesi on your team is like having a silent business partner with lots of contacts, resources, and support”

Kathleen G.

We’ve helped 30,000 people start and expand their business. Will you be 30,001?

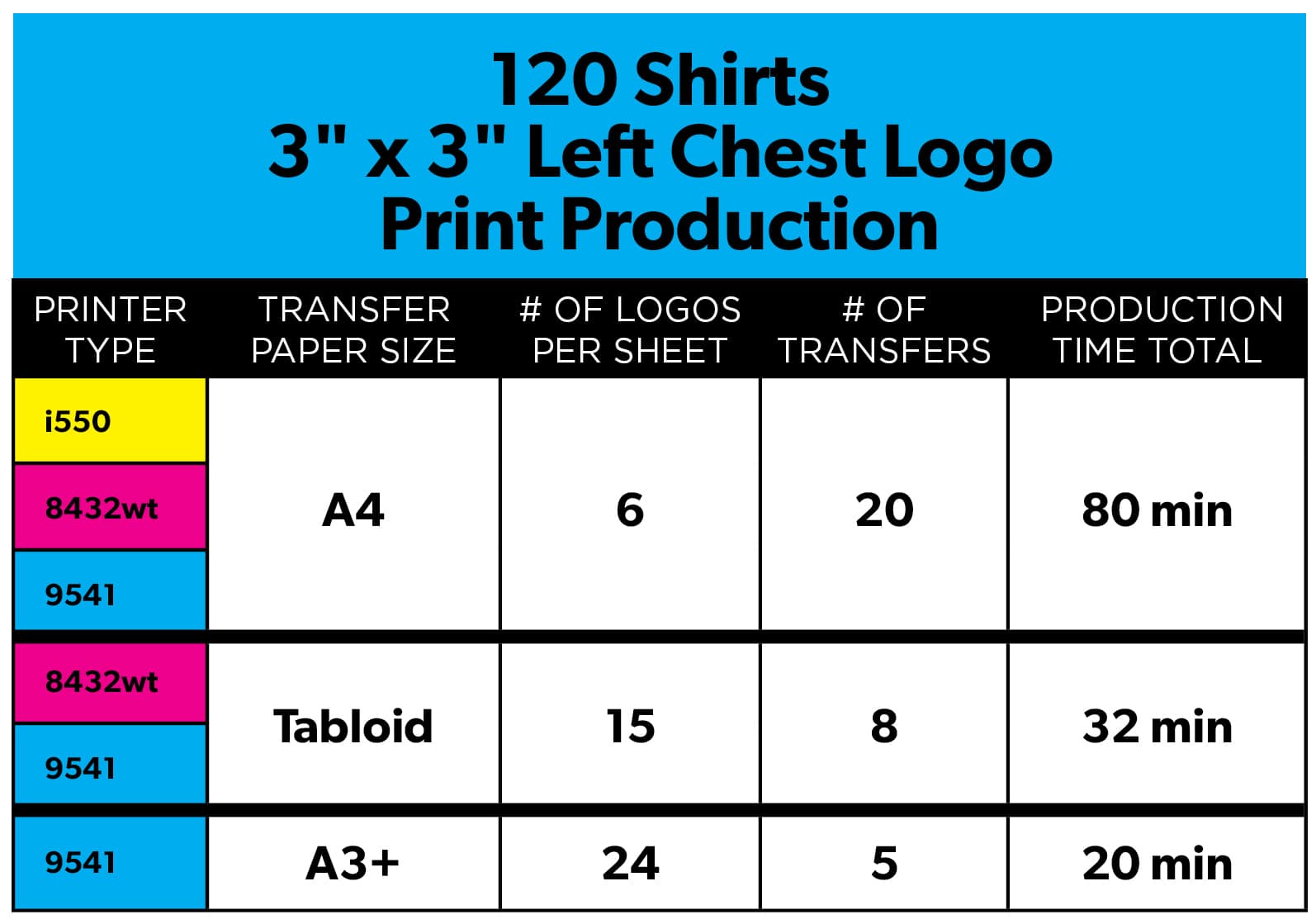

Print the biggest transfers ever

Maximum paper size of 13″ x 19″ makes the DigitalHeat FX OKI 9541wt the largest white toner transfer printer on the market. This is fantastic for a business that wants to print large t-shirt designs but even better for production. Let’s break down the typical sizes of transfer paper and compare a left chest logo that is about 3″ x 3″, imagine a typical logo on the left chest of a t-shirt. In the below scenario we will compare production times with various print sizes.

Print Job: 120 shirts with a 3″ x 3″ logo on left chest.

A4 Print

8.27 x 11.69 is about a 7.75 by 11″ print area. Yields about 6 logos per transfer sheet. Producing 120 shirts means printing 20 transfers. These all require the steps of printing, adding adhesive and trimming. Roughly 3 minutes per print.

Tabloid Print

11 x 17″ is about a 10.5 x 16.5 print area.Yields about 15 logos per transfer sheet. Producing 120 shirts means printing about 8 transfer sheets. These all require the steps of printing, adding adhesive and trimming. Roughly 3 minutes per print.

A3+ Print

13 x 19″ is about a 12.5 x 18.5 print area.Yields about 24 prints per transfer sheet. Producing 120 sheets means printing about 5 transfer sheets. Less print time + less heat press time = faster production! Compared to an A4 print, production time is reduced by 60%. Roughly 3 minutes per print. Extra large prints are essential for the most efficient production time and maximizing the potential needs of your customers.

The richest black of any toner printer

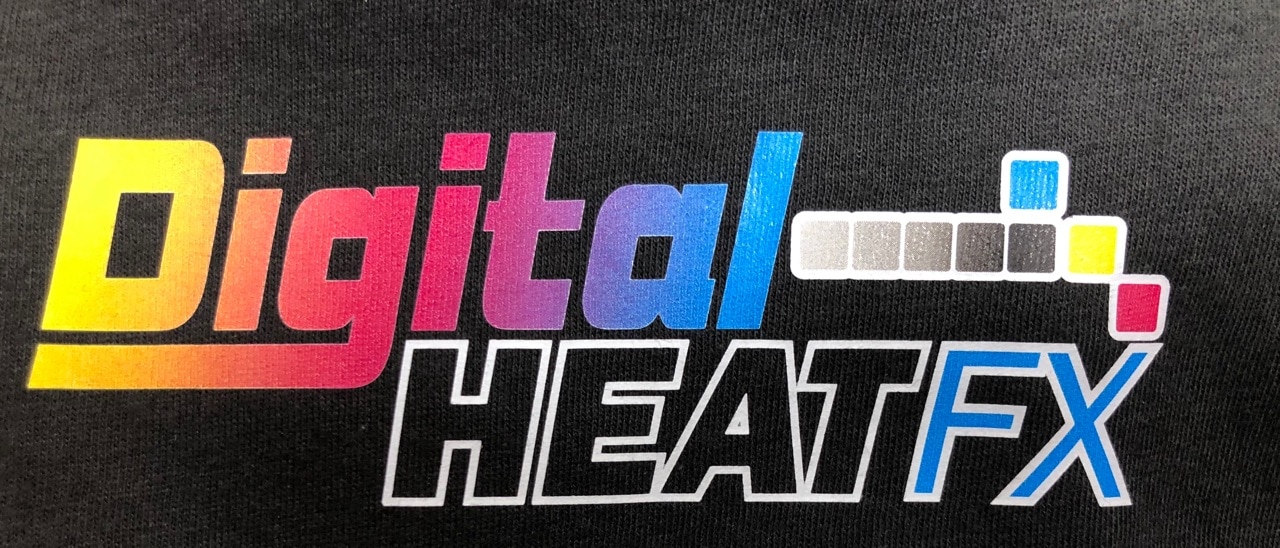

Example of printing on DigitalHeat FX 9541 with CMYK+W. Notice the detail of the gradient yellow/orange in the letter “D”.

Example of printing on DigitalHeat FX 8432 without black toner CMY+W. Notice the letter “D” is more yellow with less gradient color detail showing.

This is how our customers do short run orders every day.

1. Do a quick art preparation.

No color separation or ‘half-toning’ or any other complex tricks. Just create an image with no background. If you want an area white, just make the art contain white.

2. Print directly on to the transfer sheet.

It takes about a minute to click print and have the software process the art. The machine will print it in seconds once it get the data.

3. Add the adhesive to the print.

This is referred to as a ‘marry’ process. Essentially you put your print and an adhesive paper on a heat press. This bonds them together.

4. Take your finished transfers and adhere to your garment.

This process involves an initial adhesion and then a finish.

That’s it, a single shirt can be completed in 5 minutes. No liquid, no mess, no clean up, no other work.

If you expand this to 10 or twenty shirts, you will find that you are start-to-finish done in less than an hour. It’s a refreshing thought that you can take customers you initial turned away, and turn them into a profitable transaction. There is more to discuss within short runs, but you have to learn about the time-to-press solution first.

“This was a substantial purchase for my business, so I spent a TON of time researching white-toner printers. I ultimately bought the Digital HeatFX OKI 8432 WT [Now branded the “Crio” 8432WTD white toner printer] printer and a fusion heat press from ColDesi because they had the BEST options in terms of packages, supplies, and support that I could find. They’ve been my partner in success ever since!” —Corey Pendergraft

The ability to sell better than your competition

One of the best features of the OKI 9541wt [Now branded the “Crio” 9541WTD white toner printer] is the single-pass full-color transfer process. Many t-shirt businesses are selling based on the number of colors in a design. Generally speaking, adding more colors = adding more work. This is true for Heat Transfer Vinyl and Screen Printing. When you work with full-color transfers you print all of your colors in one shot. It doesn’t matter if its 1 color or 100 colors, its the same amount of work. Your business can use this to your advantage! While your competition is quoting on keeping the design under 4 colors, you can give your customers a vision of 100s of colors, or full-color photos being added to their apparel. This is something your competition may not be able to effectively re-create, giving you a fantastic advantage. Our transfer printing customers tell us this is one of their favorite things to offer their customers, limitless design possibilities!

DIGITALHEAT FX 9541

White Toner Transfer Printer-

DFX-9541WDT- 13" x 19" White Toner Laser Printer

-

Starter Set of Starter Toners (CMYKW)

-

DigitalHeat FX 9541 Print Optimizer

-

Printer Cable - to connect your printer to your computer

-

DigitalHeat FX EZ Peel - Transfer paper - 100 sheets each A & B (13” x 19”)

-

100 sheets of One Step (11” x 17”)

-

5 Deluxe Finishing Sheets (16” x 20”)

-

DigitalHeat FX Practice Kit ( 10 Sheets of A&B 8.5” x 11”, 10 Sheets of One Step 8.5” x 11”)

-

Forever Laser Dark 11X17 (100ct A&B)

-

$50 Blank Apparel Coupon redeemed at colmanandcompany.com

-

$50 Supply Coupon redeemed at colmandcompany.com

-

1 - Graphic Design Coupon (Up to $50) - Redeemed at coldesi-graphics

-

Includes the Industry Leading Training & Support package

-

Includes FREE 2-Year On-Site Warranty

OR

Continental U.S. Only. With approved credit. Not good with any other offer.

Easily print BIG & High-Definition images

Upgraded LED engine

Print high-quality images at a whopping 18 A4 pages /12 Tabloid pages per minute in high-definition digital LED color.

Industry Largest print area

Offer customers large high-quality images for jackets and banners with a maximum print area of A3+ 13” by 19”.

Print Optimizer Software

Easily print high-quality images without prior knowledge of Photoshop or Illustrator. No weeding necessary!

ProColor® white toner

Create stunning full-color images for light or dark materials.

Maintenance free

Because the 9541 uses toner, not ink, there is no messy clean-up, no time-wasting maintenance.

Zero setup time & full online training support

Start making sales immediately with an easy setup—even for non-technophiles—and our online training.

FREE ColDesi Training Tablet included with every new DigitalHeat FX 8432 and 9541 White Toner Printer!

Think of this as your high resolution, portable connection to your training videos, support website and even ColDesi Supplies! Use the tablet to learn more, do more and even get video support from ColDesi!

How will we help you business succeed?

Just like any other t-shirt printing technology, there is plenty to learn to become a master of toner transfer printing. This is where our experts get involved in helping you succeed. This is what you get when you work with us.

- Industry exclusive learning management system developed online training

- US Based Individual help & support via phone and Email

- Best quality supplies that are thoroughly tested and supported

- A team of experts continuously testing & improving equipment, supplies, and process.

Materials

- leather

- nylon

- neoprene

- non-woven material

- ceramics

- acrylics

- glass

- wood

- metal

Media

- t-shirts

- jackets

- signs & displays

- USB & cell phone cases

- water bottles & mugs

- canvas bags

- koozies

- sports equipment

- much, much more

Print On Anything

Your options are endless with the 9541’s super large print size and rich black printing.

- 18 A4 images/minute

- 13” by 19” inches print area

- High definition print resolution of 1200 x 600 dpi

- Paper Sizes: Tray 1: A3, A4, A5, A6, B4, B5; Multi-purpose tray: A3, A4, A5, B4, B5, A6; Custom size up to 431.8mm

- Weight: 244 pounds approximate

- 5 Color Channels (Yellow, Cyan, Magenta, Black & White)

- proColor® white toner

- Print Optimizer RIP software

- Upgraded LED engine

- 2-year on-site warranty

Interested in the DigitalHeat FX 9541 printer?

Complete this form below and one of our professional account reps will contact you.

We believe in privacy and communicating in the best way for your business. By completing the above form, you agree to be contacted by ColDesi Inc through phone calls, emails, and text messages. You can opt-out of emails with unsubscribe links or opt-out of texts by replying STOP at any time.