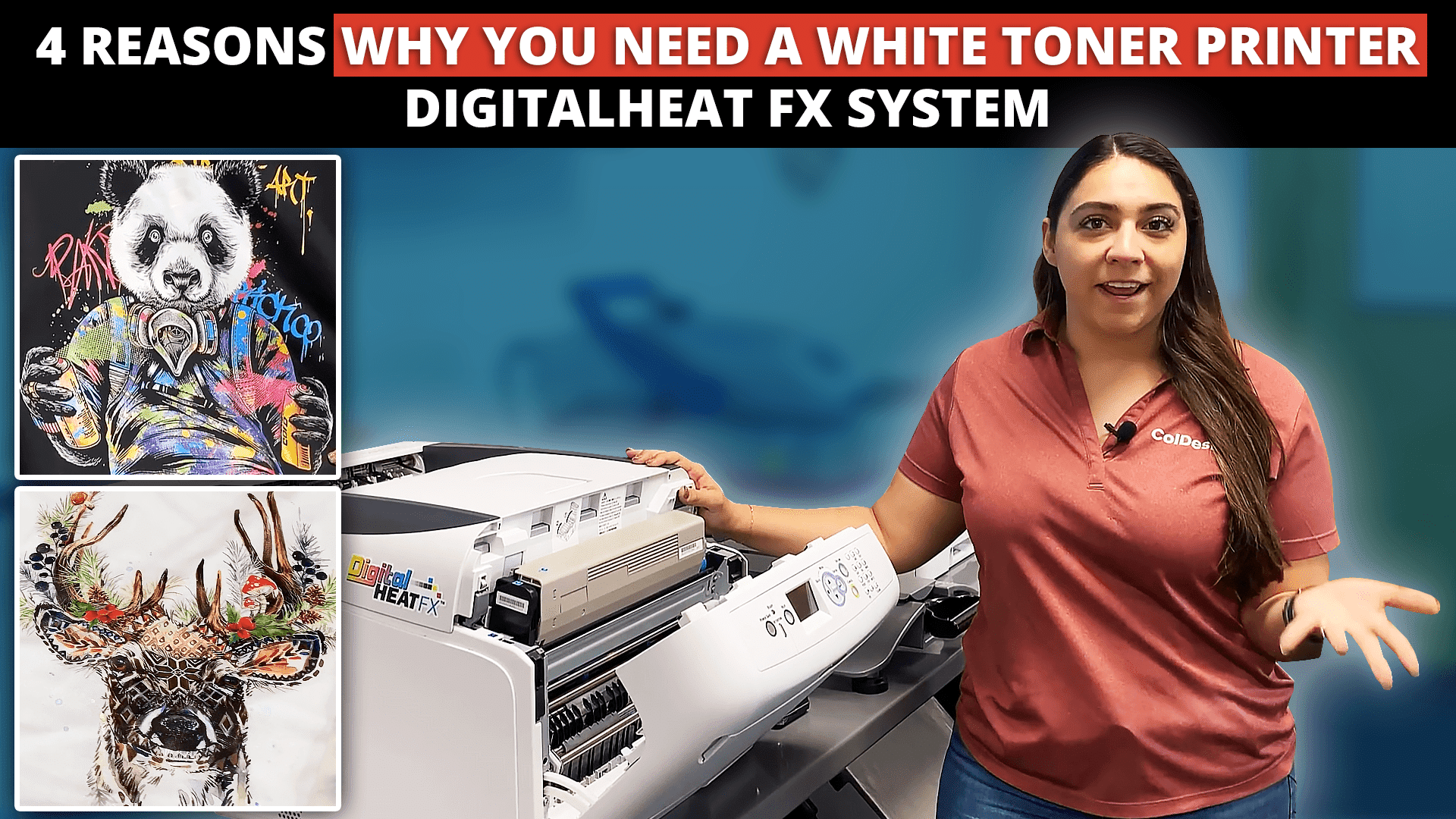

Making Custom Mugs is easier than ever before with the DigitalHeat FX System and the all new EZ Peel Hard Surface Paper.

How to apply OKI 8432 Transfers to mugs:

1. Download complete instructions from https://colmanandcompany.com/DFX_Paper.html

2. Heat your press to the desired temperature (usually between 265-390 degrees)

3. Place the transfer on your mug, wood, glass, etc using heat tape

4. Place the item into the heat press (you may or may not use a silicon pad on top – depending on instructions) for about 2-4 minutes depending.

5. When the time has elapsed, carefully remove the item from the heat press and place it in a safe place to completely cool down. Always peel the transfer paper cold. If you peel the transfer paper while the item is still warm, you will experience toner loss and the transfer paper won’t fully peel off the mug.

Finishing Process:

Some items will finish by pressing again in the heat press and others will finish in an oven. This helps increase the longevity of your print.

No longer are you held back by the limitations of sublimating mugs. With the hard surface paper you can decorate mugs of all colors and types.

Your custom t-shirt business has never been more worry-free. Talk to a pro at 855-348-4839 if you have questions or need a custom quote.