What is it REALLY like to do a small print run with a white toner printer like the DigitalHeat FX system?

You can find dozens of quick videos demonstrating the capabilities of white toner printing – many of them on this Videos page. But in the end, they are just showing you what you CAN do.

Those videos are all meant to inspire you with the possibilities and outline the capabilities of the custom t-shirt business using white toner printing.

During the video shown below you’ll see 1 person produce a 16-piece custom t-shirt order using a white toner printer.

- Starting from Printing the graphic onto the transfer sheets at :44

- Then actually making the transfers themselves through the “marry” step at 3:50 (this takes about 35 minutes so feel free to fast forward through)

- Next, we go through applying the transfers to 4 different kinds of t-shirts, 4 each, for a total of 16. That happens starting at 39:40

- Last is a finishing heat press for each shirt at 58:20 seconds

The whole process of starting from printing the graphic to finishing the order took about 1 hour.

SPOILER ALERT! We estimate that the job would earn the seller $339 in sales and $162.64 in gross profit.

Making $162.64 for an hour of work is a pretty good return on your efforts!

Watch the video below, then read on for more…

White Toner Printer – Business Advantages Vs. Screen Printing

A custom t-shirt business that uses a white toner printer has some real advantages over something like a screen-printing business for certain orders. And this 16-shirt order is a great example.

Like the fact that there was basically zero set up for this job. The 16.5” x 10.5” full color graphic we used was created elsewhere, then just pulled inside the Print Optimizer software that comes with the DigitalHeat FX systems for printing.

If you were strictly a traditional screen printer you would have had to create a separate screen for each color (that’s the simple explanation), load them on the press, prep the ink buckets, etc. So, there’s a good chance you would have declined an order like this in the first place.

But even if you did you DID accept it, you certainly wouldn’t have been able to turn around the job in 1 hour! That’s “print while you wait time”.

Vs. Sublimation

You could have done this job in about the same amount of time with a sublimation printer as using a white toner printer.

BUT, in this sample job we used 4 different t-shirts with different combinations of fabric. Like the DT104 is a 100% cotton tee, while the Bella Canvas is a blend of polyester and cotton.

Sublimation just doesn’t work on cottons and any applications to blended fabrics will leave you with muted designs.

And of course, sublimation doesn’t have white ink – like our white toner printers do – so you can’t get any kind of reasonable quality image on a dark shirt. And color shirts do most people wear?

Vs. Heat Transfer Vinyl

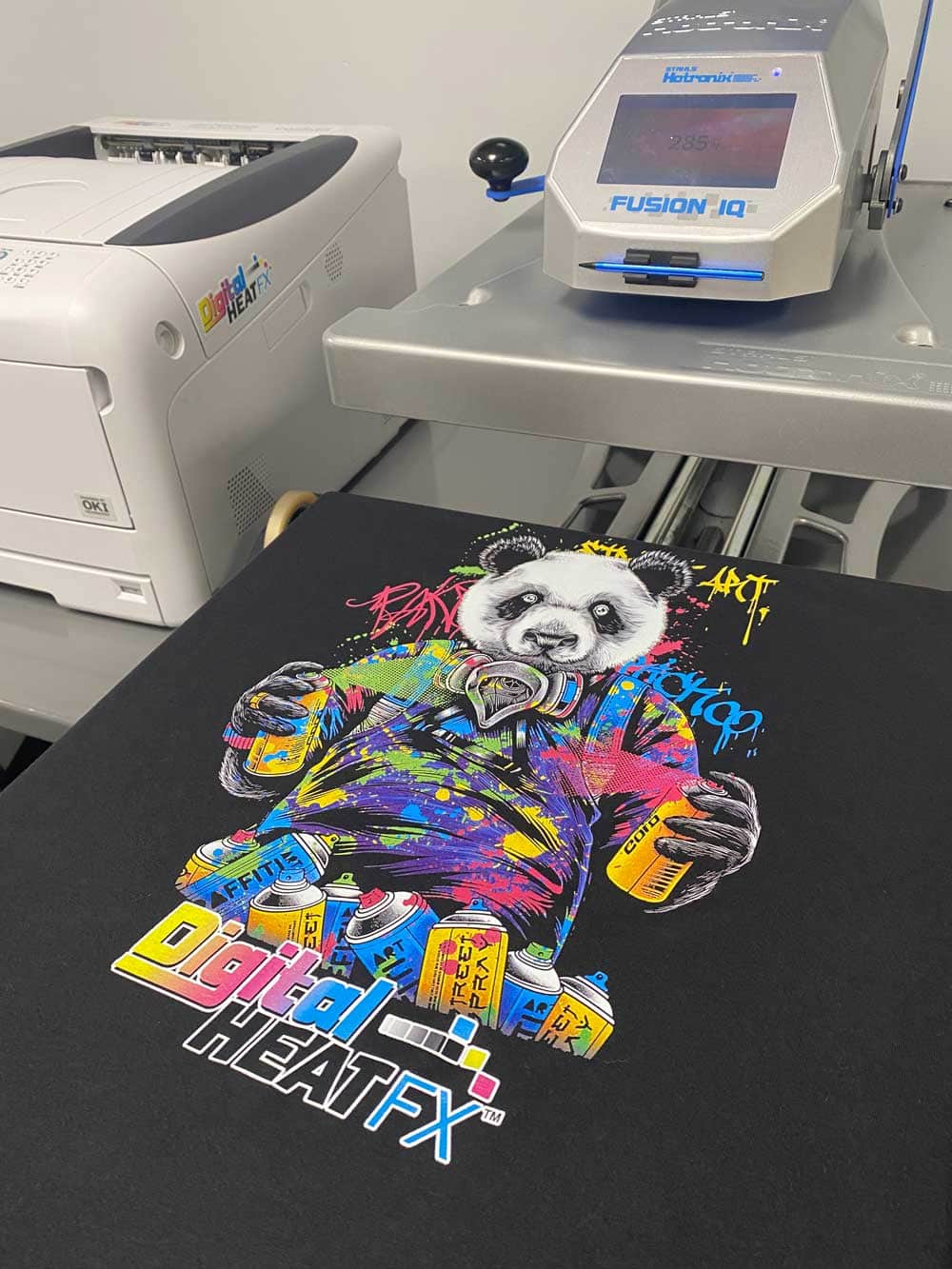

The most obvious difference here is that white toner printing offers FULL color.

You can see how colorful that Panda design is – you just can’t recreate that with traditional heat transfer viny.

Probably the most famous difference between DigitalHeat FX white toner printing and vinyl like you might use in a Cricut cutter, Silhouette or even a commercial unit like this Graphtec, is the weeding.

Weeding is when you pick out the empty spaces, or negative space, in a design. Like the middle of a letter “O” or top of an “e”.

The Case Study video show’s clearly that with white toner printing you just rip it off!

Now before we get to the ROI (return on investment) section, let’s dive into what is likely your most burning question:

How Much is a White Toner Printer?

Because how can you know how much money you can make on this 16-shirt order if you don’t understand how much everything costs?

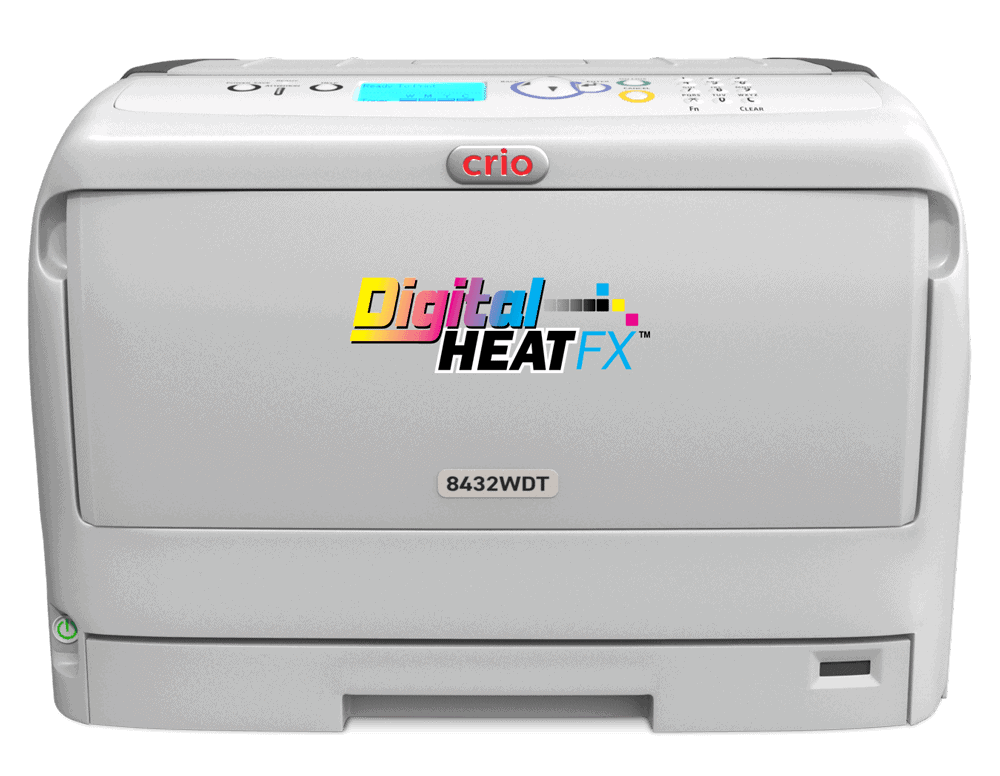

DigitalHeat FX is the most popular brand of white toner printer for small businesses. ColDesi typically bundles the printer itself with a professional quality heat press, the Print Optimizer Software needed, startup supplies and training together.

There are currently 4 models available.

Right now, a bundle will range from about $6,000 to over $15,000 but the most POPULAR model is the DigitalHeat FX 8432 we’re using in this case study.

Looking at the last 30 days of purchases, people are spending an average of $10,860.00 on their new printer. So we’ll be using that number for our ROI calculations.

Lot’s of variability in that number, so you may spend a lot more, or a lot less, but this is a good place to start. If you want to check current prices on different packages, you can compare systems here.

Financing Options for White Toner T-Shirt Printers

More than ½ the people that get into the custom t-shirt business finance their equipment purchases.

Just like any other loan, there’s a lot that goes into the monthly payment including things like:

- Credit history

- Time in business

- Price of the equipment

- Current interest rates

- Down payment

- Term of the loan

Since we can’t know every situation, we’ll use a common payment amount for our calculations and one that you can use as a starting point.

That payment is $267/month

To talk directly to a financing expert specializing in custom apparel equipment contact the pros at Adia Capital here.

Using the Right Wholesale T-Shirt

After getting the right graphic created, the next most important decision is which blank shirt to use.

The quality of the shirt, and the material you choose, is VERY important! And that influences the cost of the shirt and the profits you’ll make from the job itself.

Blank, wholesale t-shirt costs are vital to this ROI calculation.

White toner printers can print on almost any fabric. And the color typically doesn’t matter at all (though heat pressing will impact some fabrics/colors).

But the better the quality of the shirt, the better your image will look and the longer it will last. And that means the customer will be happy with your product and come back for more.

So we’re printing this 16 piece order using the 4 most popular/recommended wholesale t-shirts available today. Specifically approved for DigitalHeat FX and white toner printing.

District Perfect Weight Tee DT104

The District Perfect Weight Tee DT104 is a 100% rings pun cotton tee that is perfect for everyday wear. It`s comfortable, durable and stylish. The shirt is made of heavyweight 6.1 oz cotton and has a tagless label for added comfort and reseller branding opportunities.

It also features a double-needle hemmed bottom and sleeves for extra durability.

We use this shirt for all of our Direct to Garment Printer samples and most of our white toner printer tees.

Bellas+Canvas Unisex Heather Short Sleeve Tee

This unisex short sleeve tee is a great option for printing or embroidery. Made of a cotton and polyester blend, this shirt is soft and comfortable. It also has a heather look, which gives it a modern touch.

While we used a dark black for our sample run, this shirt is available in a variety of colors, so you can find the perfect one for your customer needs.

The Bella+Canvas tee was recommended by our customers and looks great with a DigitalHeat FX transfer applied!

Next Level Unisex CVC Tee NL621

Next Level’s Unisex CVC Tee is a soft, light-weight cotton t-shirt. The shirt features ribbed collar and cuffs for durability and comfort.

This wholesale t-shirt is perfect for printing with your customer’s logo or design in full color. It’s available at 6 different colors to suit any style preference!

Designed by Next Level Apparel, it was another shirt ranked as most popular by DigitalHeat FX white toner printer users.

District Perfect Tri Tee

District`s Perfect Tri Tee is a wholesale t-shirt available on Colman and Company. It has been an in-house favorite for many printing technologies since its inception as the first tri-blend shirt they recommended for screen printing. This tee is perfect for soft hand, color retention, reduced shrinkage and increased durability.

This shirt comes with a one-year garment warranty against any defects in fabric or workmanship caused by manufacturing process or normal wear and tear of use.

White Toner Printer Supplies

There are 3 kinds of “consumables” involved in white toner printing apart from the t-shirts themselves. You’ll see those numbers included in the ROI calculation video as part of the job costs, but here are the basics:

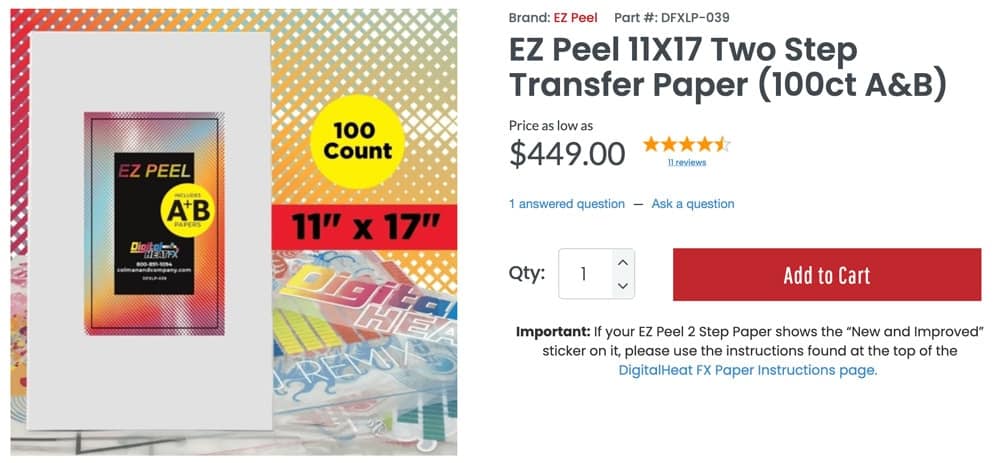

White toner transfer paper

Once you purchase your white toner printer, get training and get up and running, your next biggest regular expense after blank shirts is probably the transfer paper itself. It’s on many of our customer’s minds and sometimes people get stuck focusing on this cost of this and not on the profits they can make by using it.

In this case we used our EZ Peel 2-Step paper that’s best purchased in boxes of 100. That box will allow you to make 100 transfer SHEETS.

You can find CURRENT pricing here:

Note: There are a few different kinds of paper, including the 1 Step option for use on event shirts where you’re not concerned about washability. And hard surface paper for applying to objects instead of fabric. Chat with a pro on the Colman and Company for your options.

In the case of the huge Panda graphic, we used for the production run example, you would get one custom t-shirt print off of each 11”x17” sheet.

But there’s no restriction on smaller sizes, and you can group smaller images together on a single sheet. That means you might produce TWO 8”x5” transfers on a single sheet. Or 4 smaller ones.

Or even more left chest logos or shirt tags. All on 1 transfer.

So, while you go through the numbers provided below for this job – think about the possibilities!

- What if the graphic was ½ the size and you save 50% on transfer sheet costs?

- What if it was 10” x 8” and you could fit 4 left chest logos on the same sheet?

- How about a job JUST of left chest logos?!!

Other Supplies

There are 2 other categories of supplies you’ll need.

Finishing Sheet for your Heat Press

You’ll see in the video that when you apply a transfer to a t-shirt, you’re building a sandwich of materials.

1 – First you lay down the shirt

2 – Positing the transfer, you made on top of that

3 – Lay a re-usable finishing sheet on top of THAT

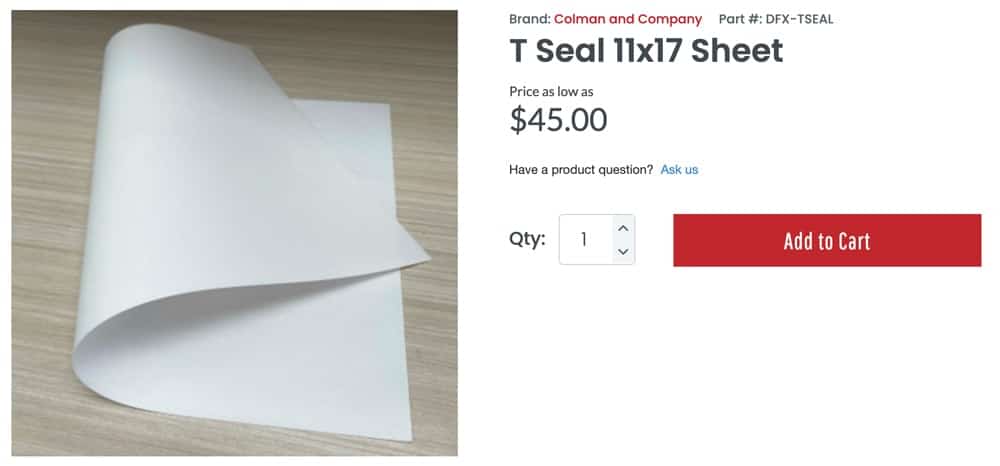

During the white toner printing production run we did we used the T-Seal finishing sheet. But there are other options.

T-Seal Finishing Sheets

During the white toner printing production run we did we used the T-Seal finishing sheet. But there are other options.

The T-Seal is one of 2 longer life sheets that also are suggested to improve the washability and give the transfer a slightly different look. And it should last you somewhere between 400 and 500 uses.

DigitalHeat FX Finishing Sheets

Our DigitalHeat FX Transfer sheets are far less expensive up front: around $19 for 50, which is around $.38/sheet. And that sheet can last DOZENS of applications.

Just remember that for our ROI calculations we used the pricier option!

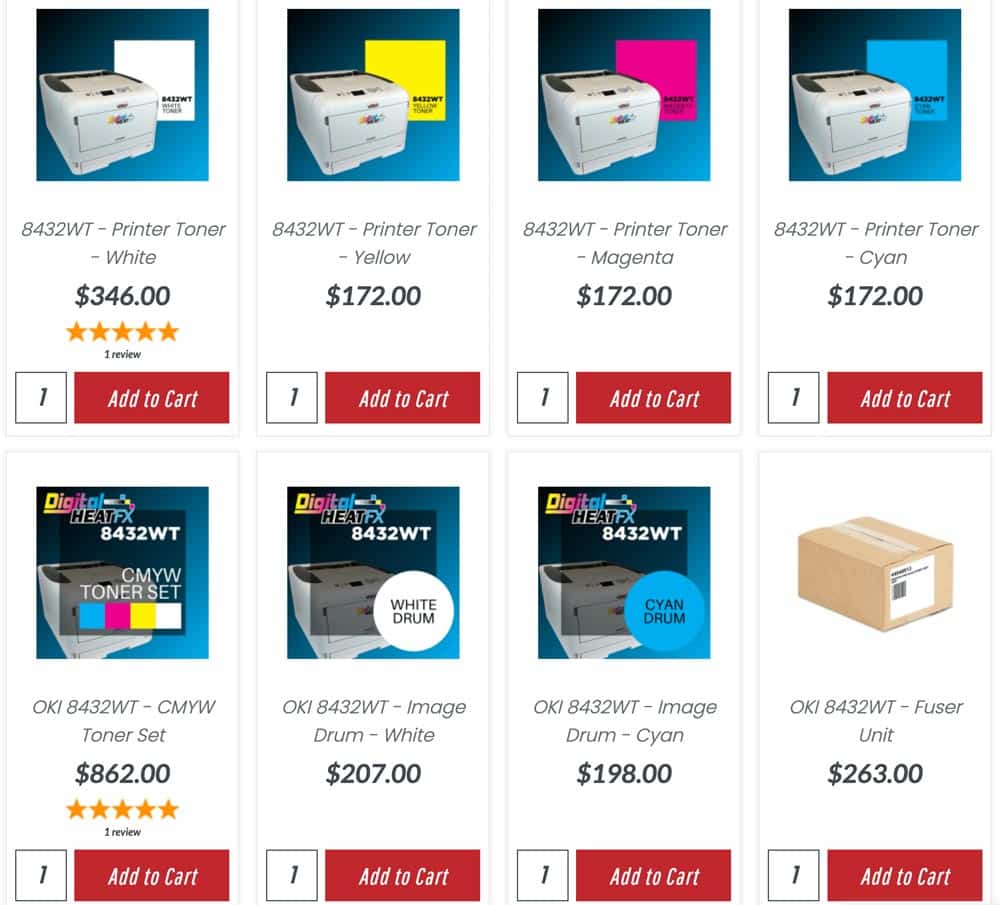

Toner, Drums and Fuser

There are a few printer items that will need replacing on a regular basis. Not necessarily OFTEN, but regular.

For example, every time you print you will use toner to do so.

The DigitalHeat FX 8432 we used in the sample job has 4 toner cartridges:

1 Cyan, 1 Yellow, 1 Magenta and 1 White. These toners are combined to make all the colors you see.

One question we get ALL the time is – How many shirts can I make with a set of toners? Which can only be answered if you can tell us exactly what you’re going to print with the entire set!

That’s because every design and every size will use a different amount of each. That article goes into more depth, but here’s an example of what you’ll spend to replace a White Toner Cartridge, it’s by far the most expensive one:

Since you can’t really tell exactly when you’ll have to replace any of the supplies or parts mentioned here there is a calculation in the Print Optimizer software that gives you an ESTIMATE. And in this particular job it estimates about $.35 per sheet.

Every time you use a sheet drop $.35 into that piggy bank so you’ll assigned the funds to replace any of these items and you’ll be good!

What is the Selling Price of a Custom T-Shirt?

On the other side of the Case Study balance sheet is sale price.

How much can you sell a custom t-shirt for?

How much can you sell this SPECIFIC custom spray painting Panda shirt for?

How to Price your Custom T-Shirts

There are several different ways to come up with pricing for any customized apparel. Each one has pros and cons and some very devoted practitioners.

There’s a thorough conversation about the different pricing methods in the podcast episode where we use Embroidery as an example. It all still applies:

But here are the basics:

1. KeyStoning

This is a cost-based method that involved calculating your costs related to a job. Usually, you would double the cost of materials, then add your additional expenses.

2. Market Pricing

That’s what we used in this Case Study. You survey the market, your competition and your potential customers and determine how much they typically pay for a similar product. Then you can decide whether you want to charge the same, a bit more or a bit less.

The best is usually some combination of those.

For example, if the market said that people pay $20 for a shirt like you’re offering but you spend $18 making it that just wont work. That’s one reason why we calculated the costs on the spreadsheet shown.

We found the market price, THEN did our cost calculations to measure profitability.

Pricing Market Survey Results

As you’ll see in the ROI video next, we surveyed people in our Custom Apparel Startups Facebook Group, White Toner Printer and Owners Groups to find out what they would charge for that specific Panda t-shirt.

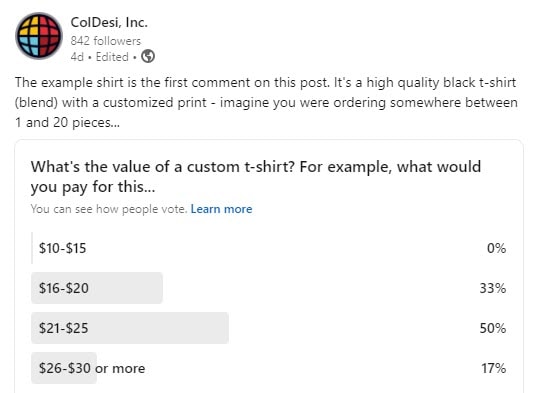

We also posted the same question on LinkedIn and got responses from a variety of consumers too.

Here’s an example of the poll results from LinkedIn:

The interesting thing about the LinkedIn pricing survey is that 67% of the respondents would expect to spend over $21 – which is a higher percentage than the people IN THE BUSINESS of selling these shirts.

That means that there’s a disconnect between what printers think they can charge and what people are willing to pay!

So, when you watch the ROI video below, think about what those differences can make to your bottom line.

Printing a Custom T-Shirt Job with DigitalHeat FX

The Process, Time and Profitability on a 16 Shirt Order

First – remember that spoiler alert?

SPOILER ALERT! We estimate that the job would earn the seller $339 in sales and $162.64 in gross profit.

Making $162.64 for an hour of work is a pretty good return on your efforts!

Here’s a quick recap:

- Number of custom t-shirts made: 16

- Time it took to make: 1 Hour

- Average Scenario Sale Price: $339

- Average Scenario Job Cost: $176.36

- Total Gross Profit: $162.38

Alternative Scenario 1

Using just the least expensive t-shirt blank.

DT104 Perfect Weight Cotton Tee at $5.19 for all 16 shirts. That brings the total cost down.

- Number of custom t-shirts made: 16

- Time it took to make: 1 Hour

- Average Scenario Sale Price: $339

- Average Scenario Job Cost: $162.24

- Total Gross Profit: $176.76

- Additional Profit $14.38/hour or 9% more GP/hour

Alternative Scenario 2

More reasonable sized graphic at 8″ x 10″.

Because you can fit TWO Panda transfers onto a single 11” x 17” sheet you cut your transfer sheet cost in ½.

- Number of custom t-shirts made: 16

- Time it took to make: 1 Hour

- Average Scenario Sale Price: $339

- Average Scenario Job Cost: $140.44

- Total Gross Profit: $198.56

- Additional Profit $35.92/hour or 22% more GP/hour

One very important note about that scenario is that it almost always applies to youth sizes. The sale price for smaller shirts is usually the same as for larger, or very close to it. So you can always make more profit because you use smaller designs!

Let’s Talk about Real Return on Investment

Using this sample job of 16 large custom t-shirts of different shirt types and a BIG design – just what do the numbers look like related to buying a white toner printer?

In the video we used $10,680 for a DigitalHeat FX Printer because it’s what most people spent in the last 30 day period when we researched this article.

There are 2 ways we calculation Return on Investment:

Using those numbers, you saw that you would make $10.17 per shirt in gross profit.

Standard Scenario

Sticking with those numbers, here’s what your ROI would look like:

Standard Scenario 1: Purchase

Average Scenario Gross Profit per Shirt: $10.17

Purchase price: $10,680

1,051 shirts at $10.17 Profit = $10,680

So if you sold just about 130 shirts per week it would take you 2 months to pay back that money

NOTE: Yes, we realize that there are other expenses – none of these calculations include labor cost, rent, electricity, insurance, etc. But we can’t estimate that for your situation. Feel free to round up or down for your own analysis.

Standard Scenario 2: Finance

Financed for $267/month:

Average Scenario Gross Profit per Shirt: $10.17

Purchase price: $10,680

26 shirts/month at $10.17 Profit = $10,680

Because $10.17 profit per shirt x 26 shirts is $267!

So if you were STILL selling 130 shirts per week you would be generating $5,288.40 in gross profit and spending under $300 on the monthly payment.

Now consider those 2 Alternative Scenarios we discussed.

If you used the more cost-effective wholesale t-shirt you’ll make 9% more and make up your machine cost in under 7.5 weeks. Or make your payment by selling just 24 shirts.

Selling the same design at ½ the size?

That’s another 22% in gross profit which will allow you to pay your machine money back selling a TOTAL of just 861 shirts. Or make your payment by selling about 21 shirts.

Conclusion

These calculations show very clearly just how profitable a white toner printing business can be. The process was relatively simple and fast once we got used to the software – and the final products looked great!

If you’re looking for an easy way to produce high value, one-of-a-kind items, then a white toner printer may be just what you need. For more case studies that show the power of digital heat FX printers, check out our website. We can’t wait to see what you create!