The Wholesale Transfer Business Case Study

Making $227.80 per hour with a white toner printer making & selling transfers

The T-Shirt Transfer business can be a very lucrative part of any custom t-shirt shop. That’s especially true if you’re using a white toner printer to make wholesale transfers to sell.

The advantage to a white toner printed transfer using EZ Peel paper is that it can be applied to almost any garment. It’s perfect for both heat pressing on-site at an event, and selling to other businesses.

If you’ve ever been to a mall, event or trade show where t-shirt printing technology is displayed – you’ll know it’s a real crowd-pleaser!

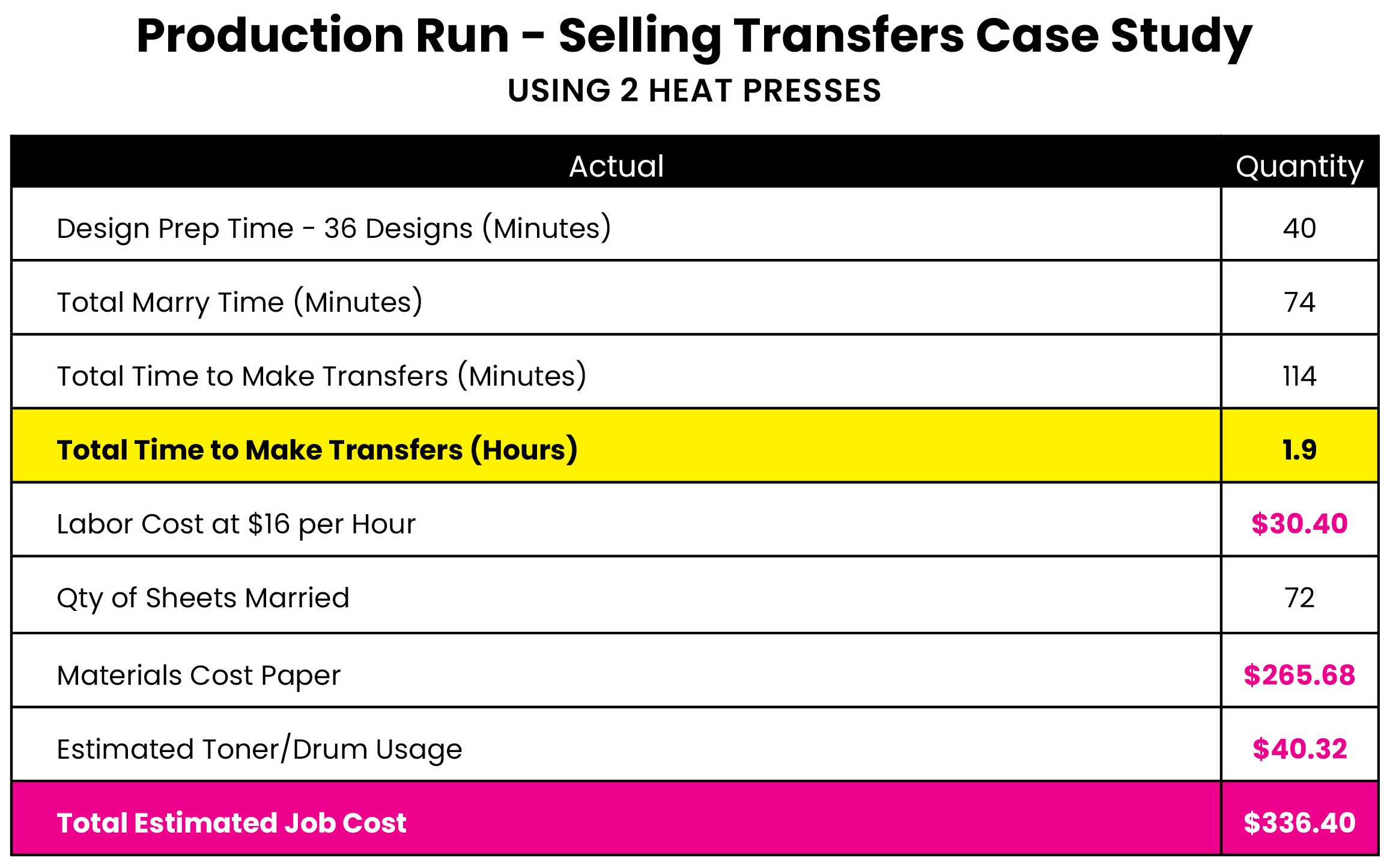

Below you’ll find real-world numbers on a typical job preparing multiple images and sized graphics for applying to t-shirts at an event.

We prepared the following quantities and sizes of transfers:

We ended up creating 36 different designs in 3 different sizes each:

- 45 in 3” x 4”

- 27 in 4” x 9”

- 119 in 8” x 8”

That’s 191 individual transfers we prepared to be heat pressed ON-SITE, “while you wait”.

The Tools

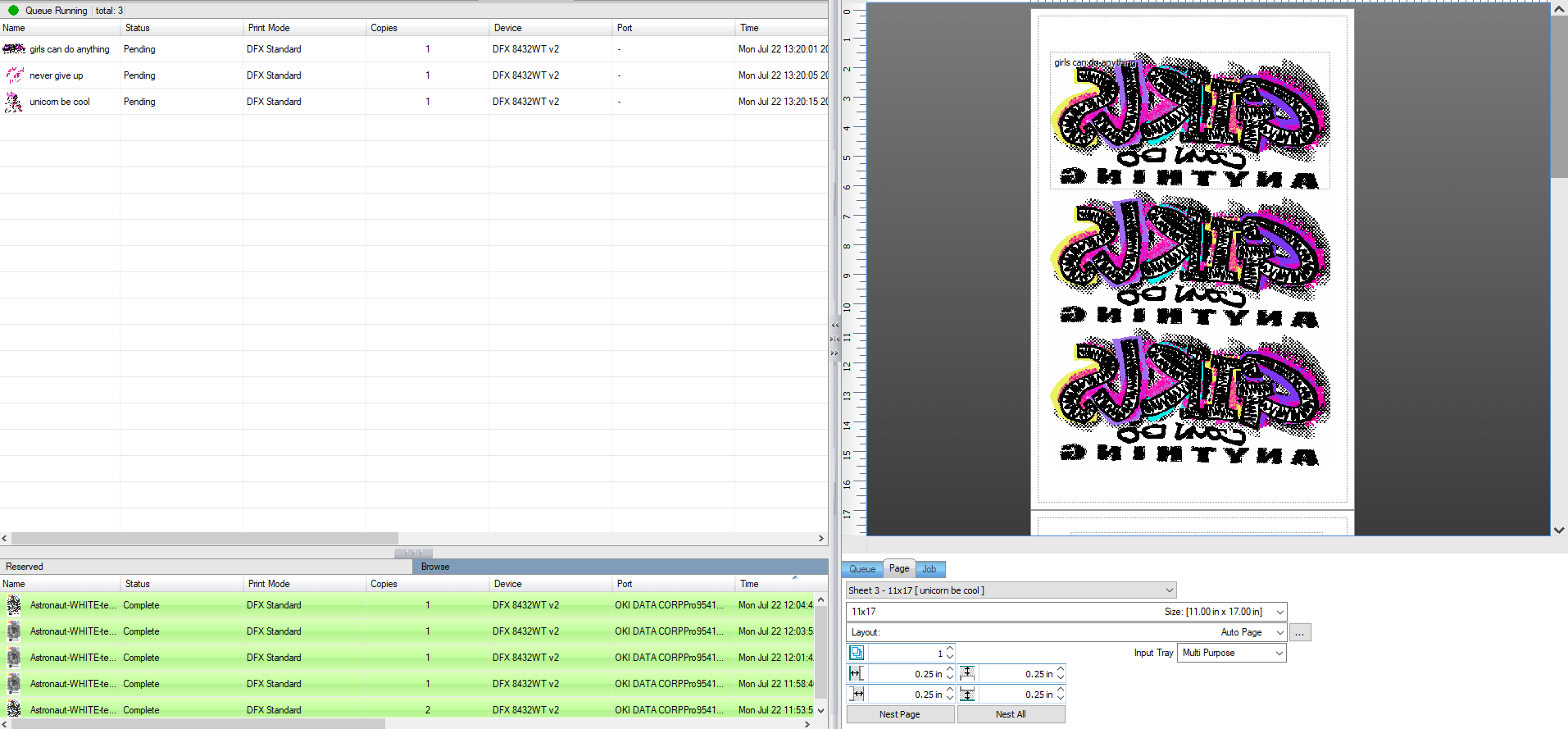

Our showroom is a 4-lane highway of visiting customers, demonstrations, sample printing, and video recordings. So, in order to keep our production time to a minimum we used the DigitalHeat FX 8432 system AND we added an additional heat press to the production line.

Normally the systems are packaged with a single, very high-quality Fusion heat press. But in this case, we thought it best to implement what we recommend to higher volume shops – and that’s to double up on the heat presses.

For higher volume white toner transfer production, the longest part of the process is the “marry” step. That’s where you attach the sheet with the adhesive to the sheet with the image on it.

Marry time for this project was 75 seconds each sheet. When you add time to arrange the transfer and peel after it’s done the opportunity for faster production by adding another heat press become clear.

While one transfer is being married on heat press 1, another can be getting set up on heat press 2. Back and forth. Back and forth.

Our equipment list included the DigitalHeat FX 8432 and TWO Fusion Heat Presses.

Supplies and Set Up Time

(To Create the Transfers)

The designs were strategically arranged on seventy-two 11”x17” sheets of DigitalHeat FX Laser EZ Peel Paper and printed out on our bundle that includes the OKI 8432WT White Toner Printer.

Each sheet cost $3.69 at Paper Saver’s Club prices and it comes in boxes of 100.

You can see there’s also a reasonable allowance for toner and drum usage in the table included here, but the bulk of the supplies expense for the print is in the paper.

We we were selling 191 transfers of the specified mixed sizes wholesale.

As you’ll see in our Actual Production Run table below, the art set up and marry time ended up being 1.9 hours overall. We used a labor cost of $16/hour.

The entire job in labor and supplies to get to the point where would could sell the transfers cost us $336.40.

Profit Calculations for the White Toner Transfer (Market Price)

Of course, we didn’t sell these transfers (we would never compete with our customers), but we DID research what the job would likely sell for on the open market.

And the FUN part was discovering the profitability!

Most owners of the DigitalHeat FX system that sell transfers to other businesses do so by the sheet, and price them depending on quantity.

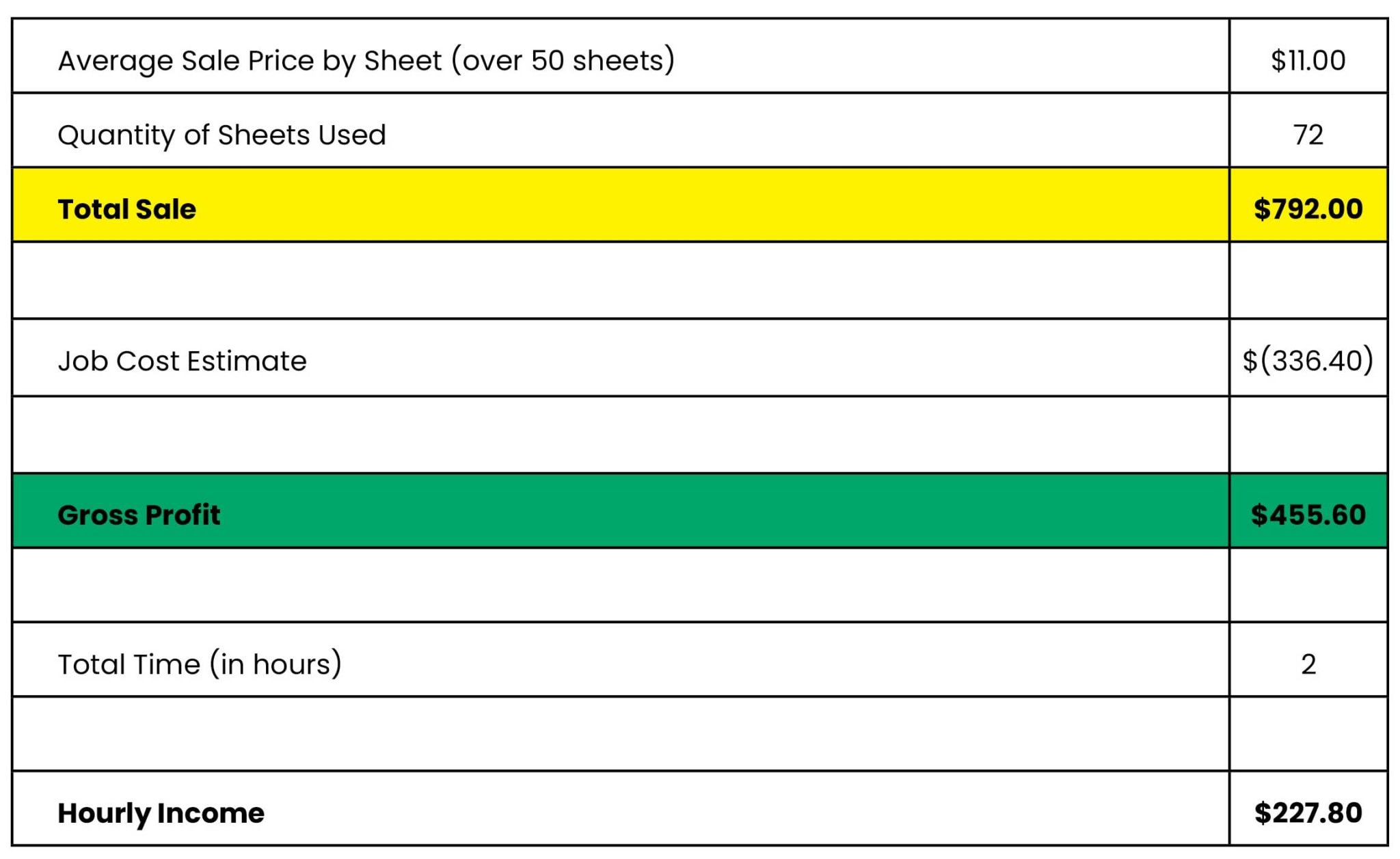

For over 50 sheets of transfers the average selling price was $11 each, so:

72 Sheets x $11.00 each = $792.00 in revenues

When you subtract our Total Estimated Job Cost as it was figured above, this is what the profit looks like:

$792 – 336.40 = $455.60 in Gross Profit

The crazy part is that because we did this job in under 2 hours – INCLUDING ART SET UP – we would have earned:

$227.80/hour

Not bad.

Return on Investment

But this is where the story gets VERY, VERY good.

Your R.O.I. is basically a measurement on how long it will take you to pay off your equipment purchase. Literally your return on your investment.

Using this job as an example as well as our supped up DigitalHeat FX bundle with the TWO Fusion heat presses it would take you about 59 of these jobs before your equipment paid for itself.

59 Wholesale Transfer Jobs x 1.9 hours per job = 112 hours of work before you’re at break even.

That’s 2.8 weeks of actual t-shirt transfer making work.

And your equipment is paid for.

With our standard DigitalHeat FX 8432 bundle (just one heat press) it would take you longer to do each job.

But it would take you fewer jobs like this to reach breakeven on your equipment purchase.

*There are other costs associated with running your business of course, but this is a pretty accurate representation of the profitability on this job.

Why Not Screen Print These

Many people might mistakenly recommend having an order like this screen printed and then just resell the transfers you purchased from another vendor. While that’s certainly an option, here are a few reasons you’ll want to keep this business in house:

- WE DIDN’T CARE HOW MANY COLORS WE USED

One of the best parts about digital white toner transfers is that you can print whatever you want to without regard to the number of colors.

- WE CHANGED OUR MINDS A LOT

And your customers will too. With the DigitalHeat FX system were able to make any size and color changes on the fly.

- MISTAKES HAPPEN

One of the transfers was created using a previous version of the artwork. We did have to pay for an extra sheet of EZPeel, but didn’t have to wait for shipping a new transfer, change or set up charges.

- UPSELLS ARE EASY

Because it’s simple for you to add flair, text, special effects, at the time of printing. That should impact your average sale price and so your profits.

What’s Next?

If you want to talk to someone specifically about getting into the wholesale white toner transfer business, you can call 855-348-4839

-or chat with us now or visit this link below and complete a contact form and we’ll be in touch.

If you’re interested in learning about how much money you can make selling completed shirts – read Part II here.