So, let’s say that you’ve worked your way through the PTA committee. And they decided to give you a shot at that big job you’ve been looking for all year long. You know you purchased the best heat press machine you could find and have the best materials.

Now, after a week of ordering, organizing, producing the job, you’re almost finished. You’re on the last set of heat press items.

Problems, Problems Problems!

Chances are this is some of your best work. Then, suddenly you’ve run into a huge problem

Around the edges of your transfer sheets, sections of the transfer won’t adhere to the garment. Your wasting garments and don’t have time to order more. What do you do?

Well, this happens from time to time to everyone. So keep reading, and I’ll give you some tips to help figure out what’s happening.

But first, have you ever thought to test your heat press machine?

You don’t want to be guessing. As a business owner, you know you’ve got to get the job out on time or lose the contract.

What Causes Heat Press Machine Failures?

The fix for this dilemma is simple, but you’ll need to learn a little bit about your heat press machine.

Each manufacturer builds their heat press machines using various techniques. They create machines that have different spacing and density of the heating elements. If you’re going to put your name on the line, you’re going to want to take a few easy steps. It’s critical to making sure that your heat press machine performs at its best.

The reality is that some manufacturers use less reliable heating elements. Or they space them out in ways that save money but do not promote even heating. With some machines, when set at 360°, they may have areas between heating elements or edges that are up to 20° cooler.

Other Problems and What You Can Do About Them

And, the larger the heat press machine, the easier it is for hot or cold spots to develop. But don’t worry because as you’ll see below, you can take control of this potential problem.

As long as you’ve done your best to find a heat press machine that is reliable you should be okay. You get what you pay for. You don’t want to buy the cheapest heat press machine on the market.

Next, you’ll want to pick up some testing strips and another device which I’ll tell you about. Consider also a monthly routine to check the different areas of your heat press machine.

Examining the Causes of Hot and Cold Spot

- Too sparse placement of heating elements

- Warped platens caused by overheating beyond 500°

- Cracks in the bottom rubber pad or wrinkles in the Teflon sheets

- Bent platens (caused by dropping the machine)

- Is there Insufficient thickness of the heat platen? As on cheaper models or defects.

- Ineffective and inaccurate heating element designs

Solutions for Hot and Cold Spots

- Replace the rubber pad if it has rips, tears or cracks which may be preventing even heat. Use a Teflon® pad protector to prevent wear and tear of the rubber pad.

- Replace the upper platen in the heat press machine. Even the best heat press machine can get damaged or warped if misused. (Note: this alone will not solve your problems if it was designed poorly.)

- If you still don’t get consistent results., consider replacing your heat press machine. Look for one that has a thicker platen and more heating elements.

Accuracy Is The Solution to Getting the Best Heat Press Machine Results

Whenever you buy a heat press machine, you’ll want to make sure that it’s accurate. And the industry standard for testing it is to use heat press test strips.

You can buy them as part of a heat press test kit, or you can buy them separately.

There are other options as well. Nearly any hardware or home store will sell digital laser thermometers. They look like a Star Trek phaser. They shoot a laser at the surface of the garment or heat press element and can take a thermal reading.

They’re not very accurate, however. Laser models can vary by more than 15 degrees. If you aim them in the same direction each time, they will indeed give you a consistent result. But, their overall accuracy may be off by quite a bit.

Aluminum platens can also give false readings with the laser style temperature guns. False readings can cause you to set the temperature of the press improperly. And that can wreck the garment you’re about to sell to your customer.

If your work washes away or falls off, your customer may find another provider.

The Best Way to Test-Heat Strips and Digital Thermometer (Pyrometer)

The very best way to guarantee temperature accuracy is with test strips. They are chemically treated to guarantee temperature accuracy.

On top of that, I recommend you purchase and use a digital heat press thermometer. This unique setup guarantees the correct temperature as well as checks for consistency.

This reusable digital technology will help you identify cold spots or hot spots. You’ll be testing your heat press element. The digital heat press probe method provides the best surface temperature readings

These pyrometers have a highly accurate temperature sensor. They feature a K-Type thermocouple to provide exact measurements of the platen. This is based on actual contact with the surface.

In a recent example, our infrared digital temperature reading was 15-18° cooler than the reading on the digital pyrometer.

Reviewing the Best Heat Press Machine Testing Procedures

- Set the temperature at 360°F; 182°C at medium pressure. #5 on Hotronix®

- Remove the temperature strips from the paper backing.

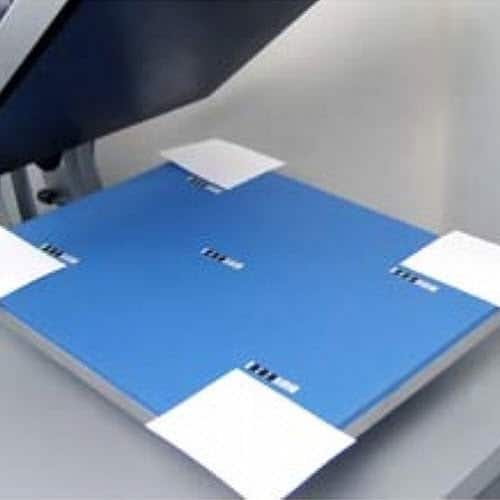

- Position the test strips in the four corners on the lower platen with part of the paper hanging off the edge.

- Heat for 8 seconds at medium pressure. While the upper platen is locked into place, try to pull the four pieces of paper out from between the platens.

- Check pressure results. Pieces of paper that come out indicate uneven pressure and a warped platen. Inaccurate heat application and ruined garments could result if not fixed.

- Compare temperature results. The test strips will blacken to show the temperature of the platen area tested. Strips that do not appear similar are evidence of differences in platen temperature.

- Conduct spot testing regularly with the Digital Pyrometer or when you notice problems. This will make sure that as the work environment changes your results are the same.

For more info or to follow up on any of the devices above, check out the good folks at Colman & Company on the web.

They have people ready to troubleshoot problems with you or provide you with the testing tools you need to keep your business humming.